We are dedicated to meeting your business needs by offering a broad range of design and fabrication capabilities which include:

- A wide selection of pressure and temperature vessels

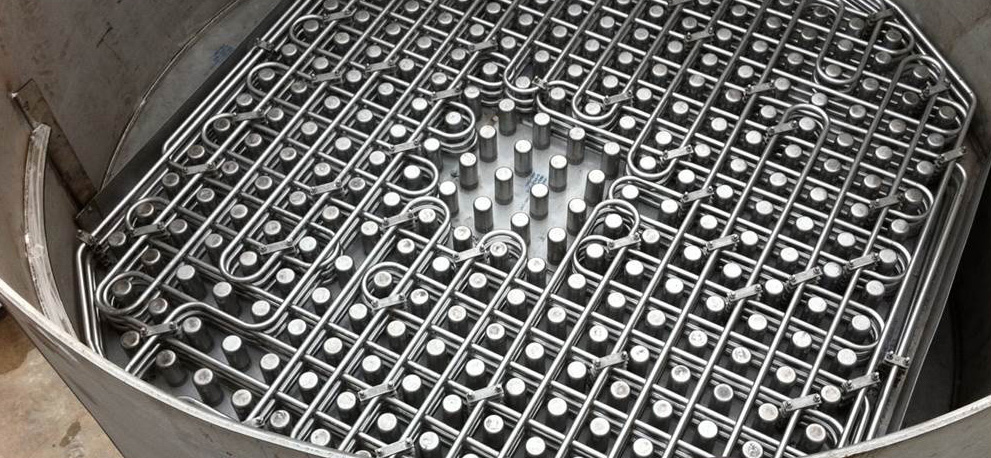

- Shell and tube type fixed tubesheet or u-tube heat exchangers

- Conventional reactors or reactors with dimpled and half-pipe jacketed columns

- Evaporators, condensers, crystallizers, towers, scrubbers, deionizers, piping systems, and modular skids

- Specialty heat exchanger rebuilds

- Our technical staff is highly-trained with extensive metallurgical knowledge, design experience, ingenuity, and flexibility utilizing the latest in computer-assisted design technologies. Our fabrication facilities contain the latest tools and equipment necessary to safely complete any project in a timely and cost-effective manner.

Field Fabrication / Repair

We also provide field fabrication services to clients at their facilities for fabrication, repair, and modification of existing pressure vessels, boilers, and heat exchangers. If your equipment is too large to transport as a complete fabricate component, we will fabricate it in sections and send a highly qualified and experienced Fabrication Services Team to your facility for final field assembly.

Certifications

We have been granted Certificates of Authorization to provide fabricated products in compliance with the American Society of Mechanical Engineers (ASME) Section I & VIII, Division I requirements.

These include:

- Compliance stamps “U” (Unfired Pressure Vessels) “S” (Boiler Manufacture Section I)

- The National Board of Boiler and Pressure Vessel Inspectors “R” (Boiler & Vessel Repair & Alteration)

- Shell and tube heat exchangers are fabricated in compliance with:

- Tubular Exchanger Manufacturers Association (TEMA)

- Unfired Heat Exchanger (UHX) B, C, and R

- AWS D1.1

- B31.1 and B31.3 Code

- American Petroleum Institute (API) – 650, 620, and 653

- American Bureau of Shipping (ABS)

Materials Capabilities:

Roberts has experience incorporating a broad range of materials into your project.

- Carbon Steel

- Stainless Steel

- Titanium

- ZeCor™

- Clad / bonded Materials

- 6% Molybdenum

- Chrome-Moly

- Ni alloys

For a complete list please

Quality Assurance and Control:

Roberts strictly adheres to a number of Quality Assurance and Quality Control Programs. As part of this process, we undergo yearly audits through our Authorized Inspection Agents and full audits every three years by the ASME and the National Board. Through the audit process and our ongoing internal efforts, we keep our quality program up to date with the latest amendments and revisions to the ASME code.

Our written Quality Control / Quality Assurance program is committed to zero defects both technically and aesthetically. All vessels are built to the same standards, whether code stamped or not. In addition to in-house radiography capabilities, we are equipped to perform various types of leak tests, (including Helium Leak Testing), proof tests, and ultrasonic thickness and material verification tests. We will develop a Project Specific QA / QC Program tailored for our clients’ unique needs.

Positive Material Identification:

- Was the correct material used in your equipment?

- Was the correct filler metal used to weld your equipment?

- What type of material do you have in that pile of steel on your site?

Shop Testing

Roberts has in-house nondestructive testing (NDT) capabilities.

- Certified Welding Inspectors (CWI’s)

- Full-time Vessel Professional Engineer (PE)

- Visual Testing (VT)

- Penetrant Testing (PT)

- Magnetic Particle Testing (MT)

- Ultrasonic Testing (UT)

- Radiographic Testing (RT)

- Positive Material Identification (PMI)

- Helium Leak Testing

Fabrication Facilities and Equipment:

Our fabrication facilities, located on 15 acres in Winterville, North Carolina, make Roberts uniquely positioned to accommodate our customers’ industrial fabrication requirements. In our 82,000 square foot shop we design and build heat exchangers, pressure vessels, columns, and tanks. We fabricate pipe as large as 120 inches from all types of materials.

Shop Equipment

- Davi Plate Roll (3.5 inches thick x 10 feet wide)

- CNC Plasma Table

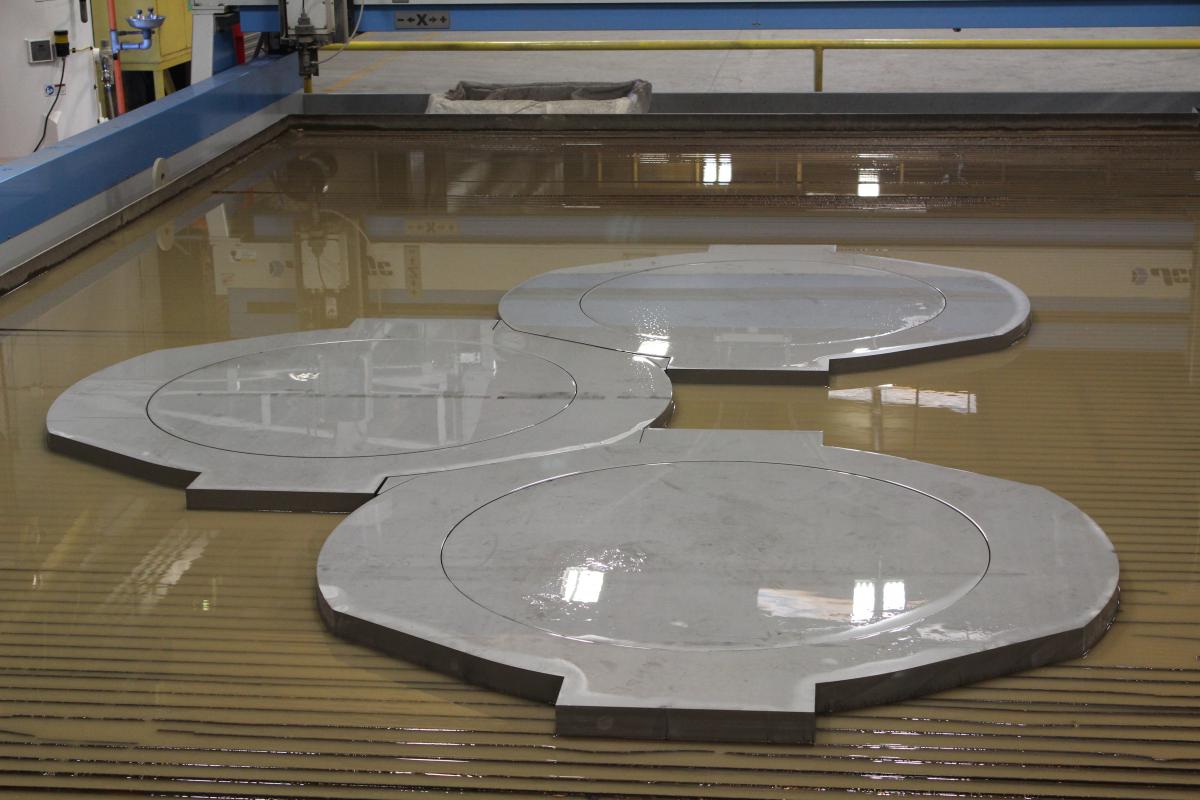

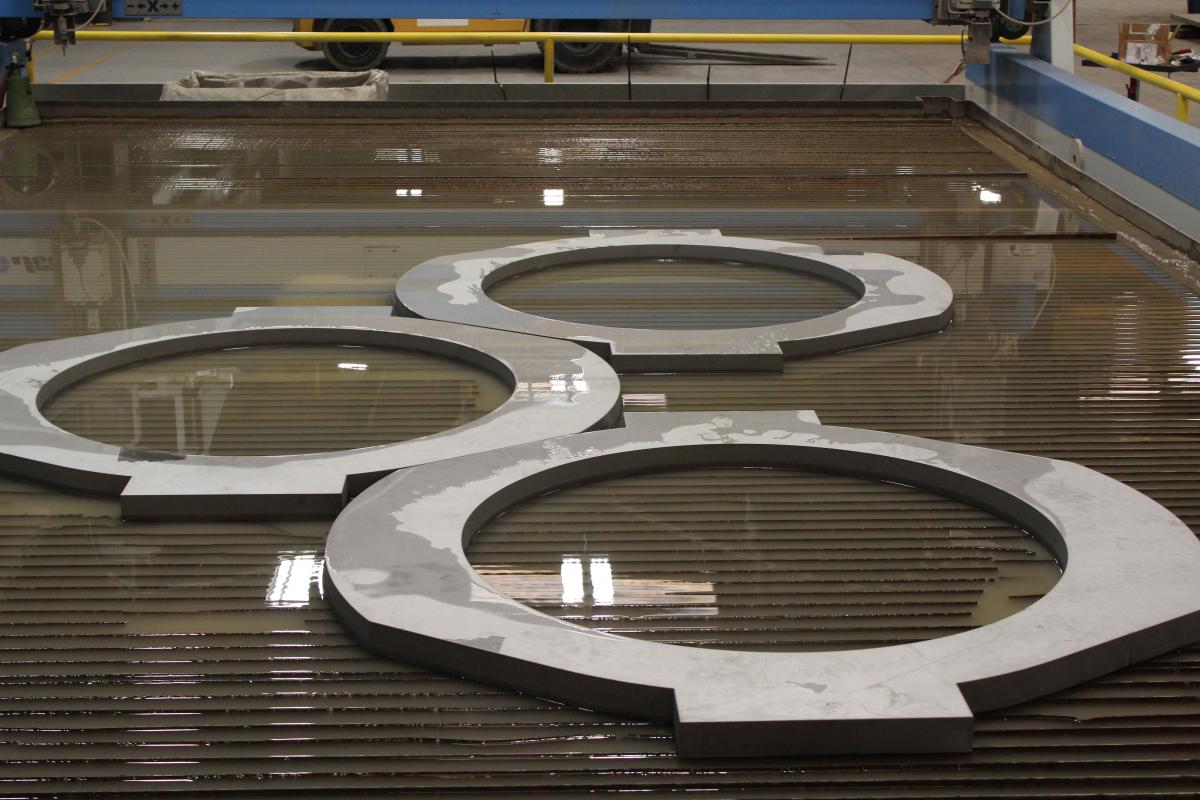

- JetEdge Waterjet

- Intimidator QuickMill Drill

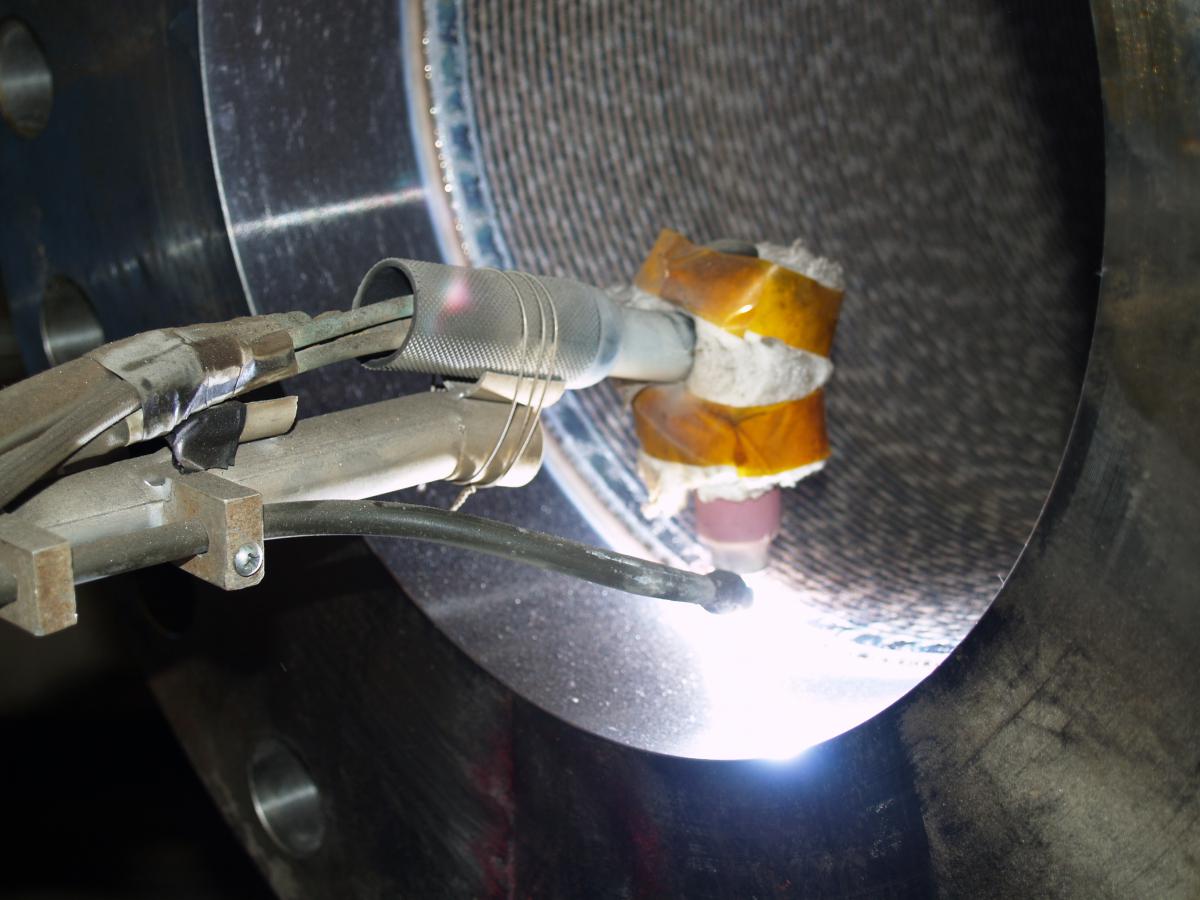

- Arc Machines PolySoude TS 8 75-2 Automated Orbital Welder

- Band Saws

- Rotary Plasma Pipe Cut-Off

- Cut-Offs

- Press Break (350 tons x 12 feet)

- Structural Bending Rolls

- Vertical Boring Mill

- Engine Lathe

- Radial Arm Drill Press

- Paint Booth

- Rotary Plasma Pipe Cut-Off

Mobile Equipment

- Multiple Tractors, Flat Beds, Drop Decks, and Double Drop Trailers

- Heavy Haul Trailer

- Mobile Cranes

- Boom Trucks

- Mobile NDE RT

Our fabrications can ship anywhere in the world through the following methods:

- Trucking: a combination of company-owned as well as specialized contract haulers

- Rail: CSX

- Marine – Port of Morehead City, North Carolina

Roberts can help you determine the value of your unknown materials before you either recycle or scrap with our mobile positive material identification services available at your location or our facility.