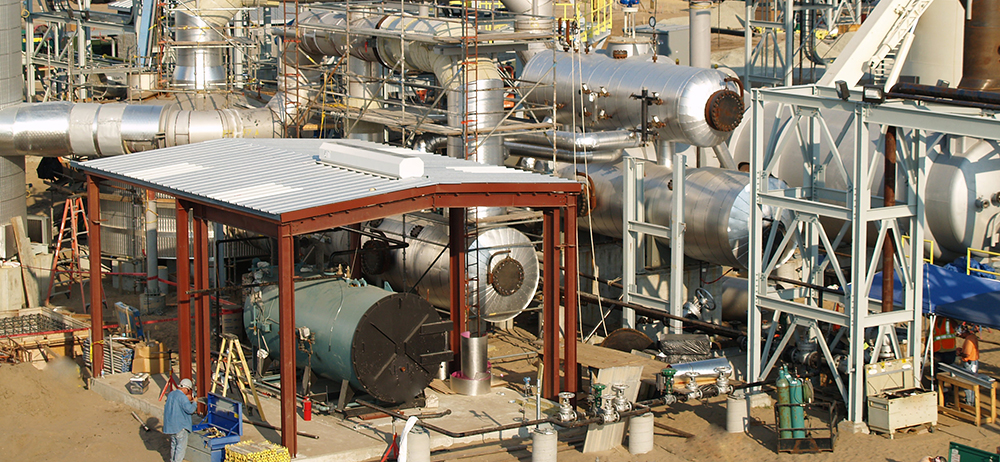

Our broad range of services include:

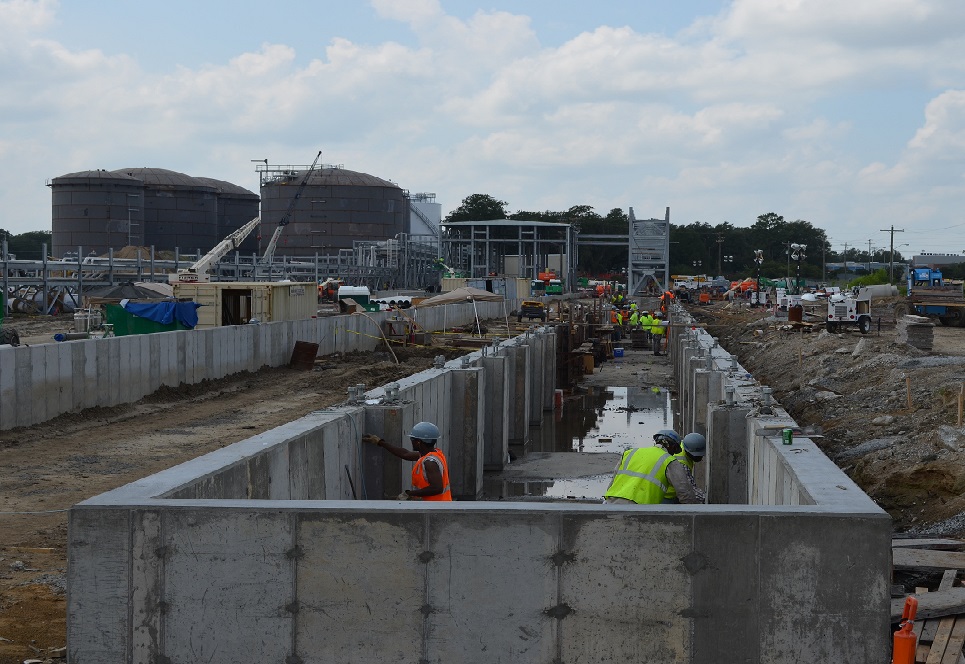

- Precision foundation concrete placement, equipment / building foundations

- Structural steel erection

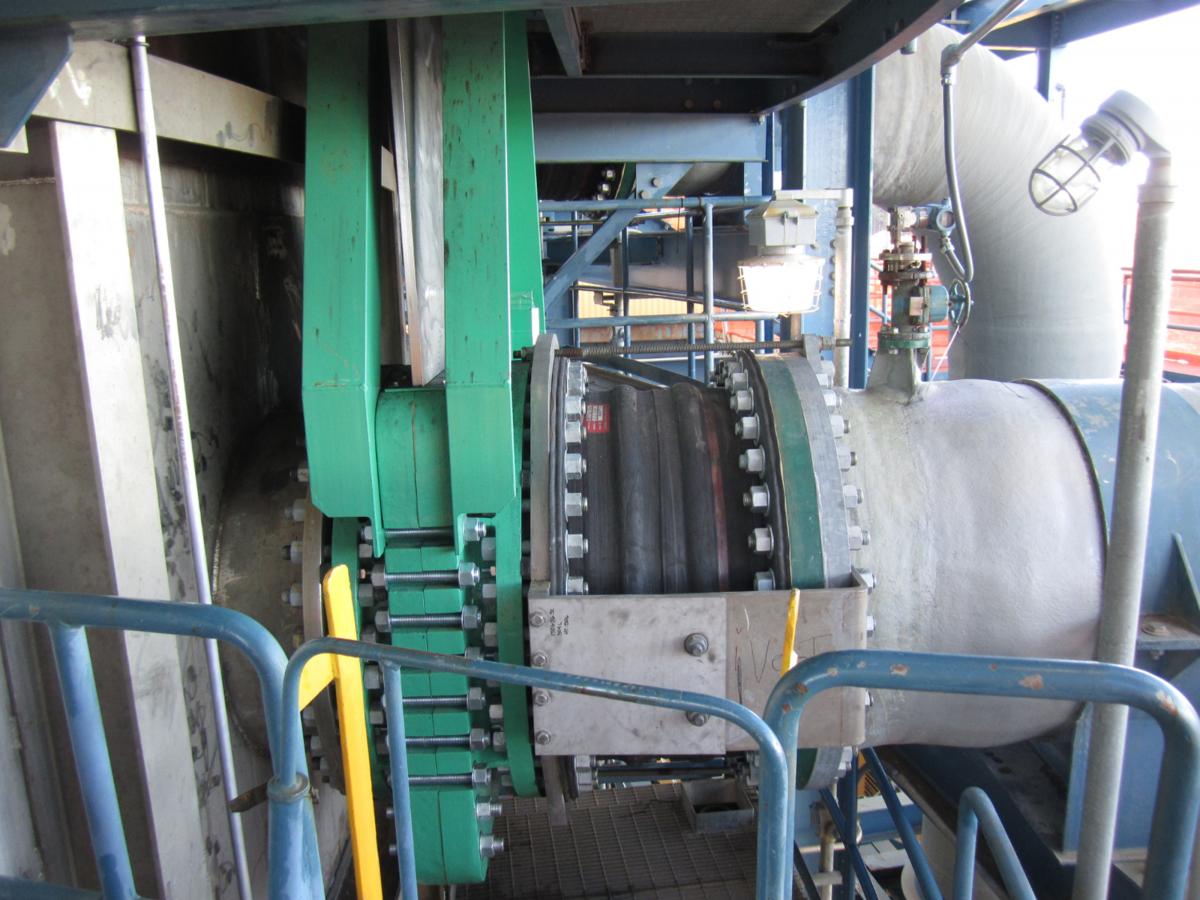

- Mechanical equipment installation, precision millwright and optical equipment alignment

- Process and utility piping

- Total plant electrical power distribution system installation including substations / switchyards

- Controls and instrumentation system installation and existing plant integration

We have extensive experience in plant construction across many industries including pulp and paper, sulfuric acid, nitric acid, acetic acid, chemical, advanced resins and polymers, cement and aggregates, mining, minerals and quarries, steel mill, power, and pharmaceutical. Our project portfolio consists of work throughout the United States.

All hiring is conducted by Roberts and all major trade work is provided by Roberts’ employees. By utilizing our own forces, we substantially increase control over the project and ensure its successful completion. Our team is dedicated to the highest standard of excellence for your project.

Certifications

We have been granted Certificates of Authorization to provide fabricated products in compliance with the American Society of Mechanical Engineers (ASME) Section I & VIII, Division I requirements.

These include:

- Compliance stamps “U” (Unfired Pressure Vessels) “S” (Boiler Manufacture Section I)

- The National Board of Boiler and Pressure Vessel Inspectors “R” (Boiler & Vessel Repair & Alteration)

- Shell and tube heat exchangers are fabricated in compliance with:

- Tubular Exchange Manufacturers Association (TEMA)

- Unfired Heat Exchanger (UHX) B, C, and R

- AWS D1.1.

- 1 and B31.3 Code

- American Petroleum Institute (API) – 650, 620 and 653

Recognition and Safety

By working harder and smarter for our customers, we have earned their trust. Roberts’ impeccable reputation is the result of our safety performance, quality workmanship, and the ability to consistently meet scheduled completion dates.

Roberts Construction and Plant Maintenance Services are consistently rated among the top major contractors in the Southeast for establishing safe and efficient working environments at plant sites. We have been recognized by our clients and our peers for excellence in construction, as well as our safety and quality performance. In addition, we have been recognized by the North Carolina Department of Labor for our exemplary safety performance, as part of their North Carolina STAR Program. Our safety record ranks among -the best for self-performing contractors in the United States. We are 100% committed to safety. We believe there is absolutely nothing we do that’s worth putting a human life at risk. Our safety program is designed to facilitate that goal.

Quality Assurance and Control

Roberts is committed to providing clients with the highest-quality workmanship, performed with continuous emphasis on safety and preplanning, to ensure a cost-effective, efficient, well-coordinated project. Our management and craftsmen can integrate new construction with existing systems to ensure a smooth transition and trouble-free startup. Our experience ensures that your project will be on-line and completed on time, within established budget constraints.

With every project, our QA/QC Management Process is initiated long before operations in the field are started to ensure that all equipment is manufactured, shipped, received, and installed in accordance with your project requirements. We manage punch list, pre-start-up checks, start-up and testing at pre-determined intervals, start-up procedures, system verification tests, and functional performance tests. Each stage signals that a phase of completion has been achieved. All phases are completed in written format per our Quality Control Procedures Manual sign-off verification forms. Our procedures ensure that we do our job right the first time.

Shop Testing

Roberts has in-house nondestructive testing (NDT) capabilities.

- Certified Welding Inspectors (CWI’s)

- Full-time Vessel Professional Engineer (PE)

- Visual Testing (VT)

- Penetrant Testing (PT)

- Magnetic Particle Testing (MT)

- Ultrasonic Testing (UT)

- Radiographic Testing (RT)

- Positive Material Identification (PMI)

- Helium Leak Testing

Project Management

Before a project begins, our experienced estimators apply valuable technical industry know-how to our in-house customized estimating database coupled with our historical project data. Careful estimating streamlines the take-off process to produce highly accurate project cost estimates.

Our scheduling capability, using the web-based Primavera P6 critical path scheduling system, shows real-time production to track project tasks. One major advantage of this software is it allows clients to view their projects’ progress in real-time from anywhere in the world.

We use Viewpoint project management and integrated control system management software for tracking all project-related activities and costs associated with our day-to-day operations. This precise monitoring produces comprehensive accounting and timely cost reporting, as well as multilevel project accounting and reporting, monthly invoicing, labor and materials reporting, and percent complete reporting.

For more than 45 years, Roberts has earned a reputation for honesty, discipline, and hard work. Our values are demonstrated in the way we work and interact with others.